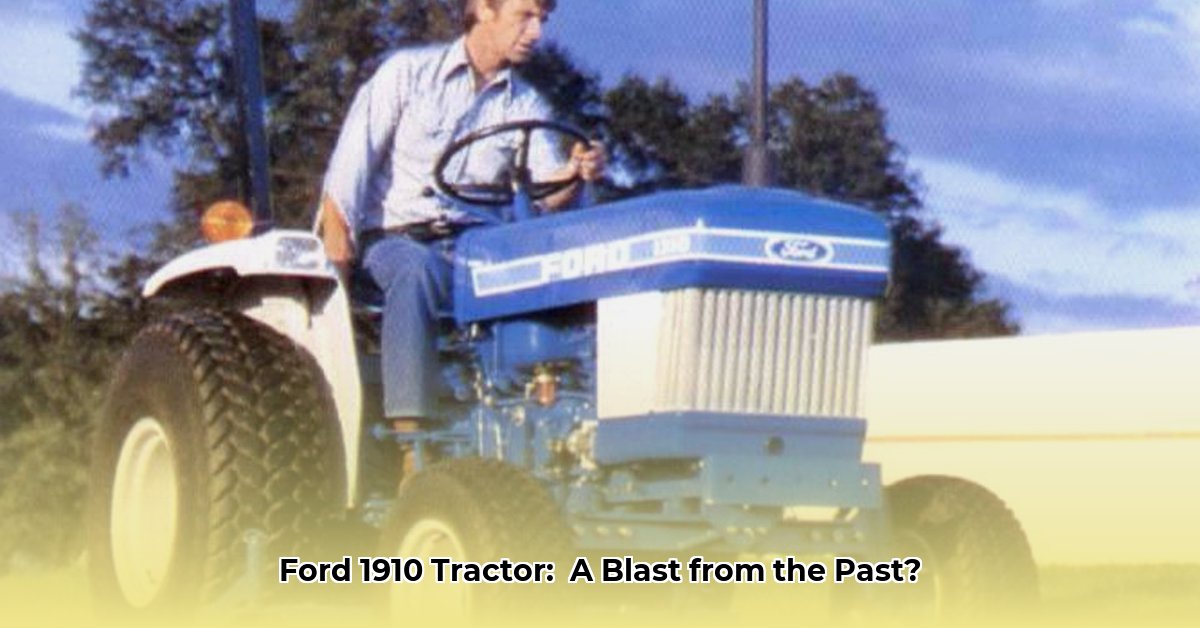

The Ford 1910, produced from 1983 to 1986 by Shibaura Manufacturing Company in Japan for Ford, stands as a compelling example of compact utility tractors from the 1980s. Unlike its larger, more powerful contemporaries, the 1910 prioritized efficiency and versatility, making it ideal for smaller farms and specialized tasks. Its relatively modest size belies its significance in the agricultural landscape of the era, representing a shift towards more specialized and efficient farm machinery. How did this Japanese-built Ford fare against its American counterparts? Let's delve into the details. For more in-depth information, check out this dedicated website: 1910 Ford Tractor.

Under the Hood: Engine Specifications and Design

The Ford 1910 boasted a 1.7-liter, three-cylinder diesel engine. While Ford advertised approximately 28.5 PTO (power take-off) horsepower, real-world performance varied slightly depending on testing methodologies. This three-cylinder configuration, less common at the time, likely prioritized fuel efficiency and reduced weight, a strategic design trade-off that prioritized practicality over sheer power. Was this a successful compromise for the target market? The impact on fuel consumption compared to competitors warrants further investigation.

The transmission system, based on available data, featured 12 forward and 4 reverse gears. However, the precise shifting quality remains unclear and requires further research. Despite this uncertainty, the design clearly aimed for efficient operation across varied working conditions.

Versatility and Attachment Capabilities

The Ford 1910's versatility made it stand out. Its Category I three-point hitch system enabled easy attachment of a broad range of implements, including mowers, snow blowers, front-end loaders, and backhoes. This adaptability significantly broadened its utility compared to many tractors of its era, which often focused on single tasks. How did this adaptability affect its overall market appeal in comparison to more specialized tractors?

The Shibaura Partnership: A Transpacific Collaboration

The Ford 1910's Japanese origins are integral to its story. Built by Shibaura (later part of Kubota), this collaboration likely shaped the tractor's design and component sourcing, potentially influencing its long-term reliability and parts availability. This partnership highlights the increasing globalization of agricultural machinery manufacturing in the 1980s. What specific aspects of Shibaura's engineering and manufacturing processes contributed to the 1910's design?

Collector's Interest and Historical Significance

Today, the Ford 1910 is highly sought after by vintage tractor enthusiasts. Its rarity contributes to its collector value, making it a prized possession. Beyond its engineering characteristics, the 1910 provides valuable insight into the evolving agricultural equipment market of the 1980s. Its story within the larger narrative of agricultural innovation warrants continued study.

Stakeholder Perspectives and Actions

The Ford 1910 holds different significance for various stakeholders:

- Collectors: Should prioritize meticulous inspection during purchase, proactive parts sourcing (potentially including 3D printing), and detailed maintenance records. Connecting with online communities is crucial.

- Agricultural Historians: Should focus on researching sales figures, analyzing Shibaura's design contributions, and compiling comprehensive production data to understand its market impact.

- Vintage Equipment Dealers: Need to maintain a stock of common replacement parts and target collectors as their primary customer base while preparing for potentially long-term parts supply challenges.

Challenges of Ownership and Mitigation Strategies

Restoring and maintaining a Ford 1910 presents several challenges:

- Parts Availability: (Moderate likelihood, High impact) Proactive parts sourcing and creative problem-solving (including 3D printing/fabrication) are essential. Online communities become essential resources.

- Mechanical Problems: (Moderate likelihood, Moderate impact) Thorough pre-purchase inspection and budgeting for repairs are crucial. Preventive maintenance is paramount.

- Value Decrease: (Low likelihood, Low impact) Prioritize well-maintained tractors and consider professional appraisals for accurate valuation.

- Information Scarcity: (High likelihood, Moderate impact) Active searching for original manuals and service documents via online forums and enthusiast networks is critical.

Always prioritize safety: When working with any vintage machinery, strictly adhere to all safety regulations. The Ford 1910, though compact, presents a fascinating case study in agricultural technology and the transpacific collaborations that defined the 1980s. The full story of its design, production, and impact on the agricultural landscape remains a topic deserving further exploration.

Troubleshooting Transmission Issues: A Practical Guide

Key Takeaways: Transmission problems in a Ford 1910 are often due to worn shift forks, rail wear, or excessive play in the shifting mechanism. Diagnosis requires careful inspection and potential transmission disassembly. Parts scarcity underlines the importance of resourceful problem-solving and community support.

Initial Assessment: A Visual Inspection

Begin with a thorough visual inspection of the shift forks, rail, and linkages. Look for wear, damage, or excessive play. Document findings photographically.

Step-by-Step Troubleshooting:

- Shift Mechanism Assessment: Examine the linkage for bends, breaks, or excessive play. Tighten any loose components.

- Shift Forks and Rail Inspection: Requires partial to full transmission disassembly. Photograph each step methodically. Look for wear, scoring, and alignment issues.

- Engagement Check: Manually move shift forks after disassembly. Check for binding. If excessive play exists, consider shimming.

- Internal Component Inspection: If surface-level adjustments fail, full transmission disassembly is necessary. Proceed with extreme caution.

- Seek Expert Assistance: Engage experienced mechanics or online tractor restoration communities for guidance.

Parts Acquisition and Community Support

Finding original parts is difficult. Fabrication or adaptation of modern components may become necessary. Online forums and communities are vital resources for parts sourcing and troubleshooting assistance. Preventive maintenance and mindful storage practices minimize wear and tear for this challenging-to-restore classic.